Connect industrial field devices to OPC UA servers through OPC UA gateways

Views : 9924

Author : Jeakie

Update time : 2023-04-07 10:26:44

Connect industrial field devices to OPC UA servers through OPC UA gateways

At present, most PLCs on the market are connected to OPC UA Server through OPC UA software running on industrial PCs, which requires both industrial PCs as hardware and the purchase of OPC UA licenses, which is expensive.

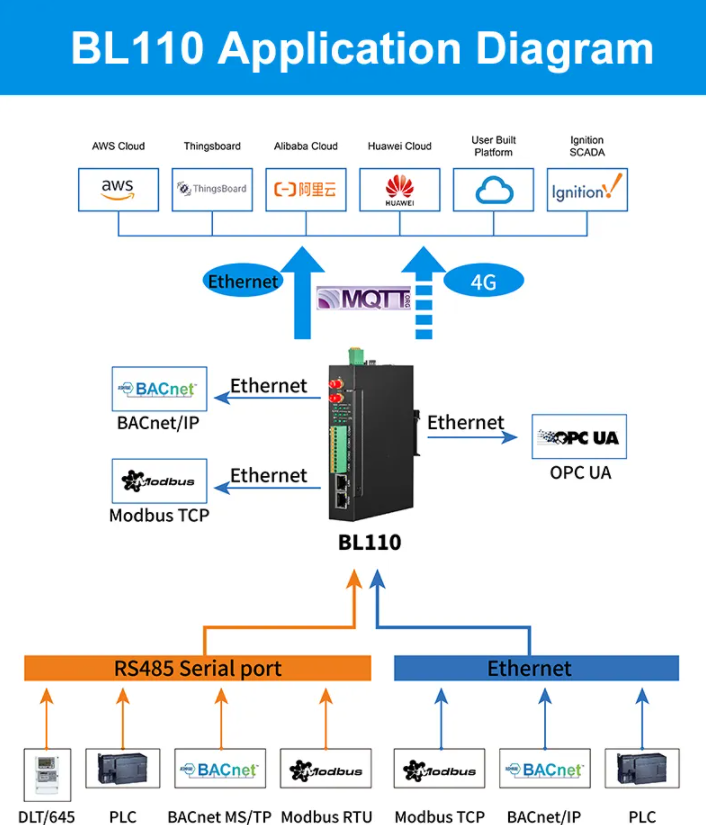

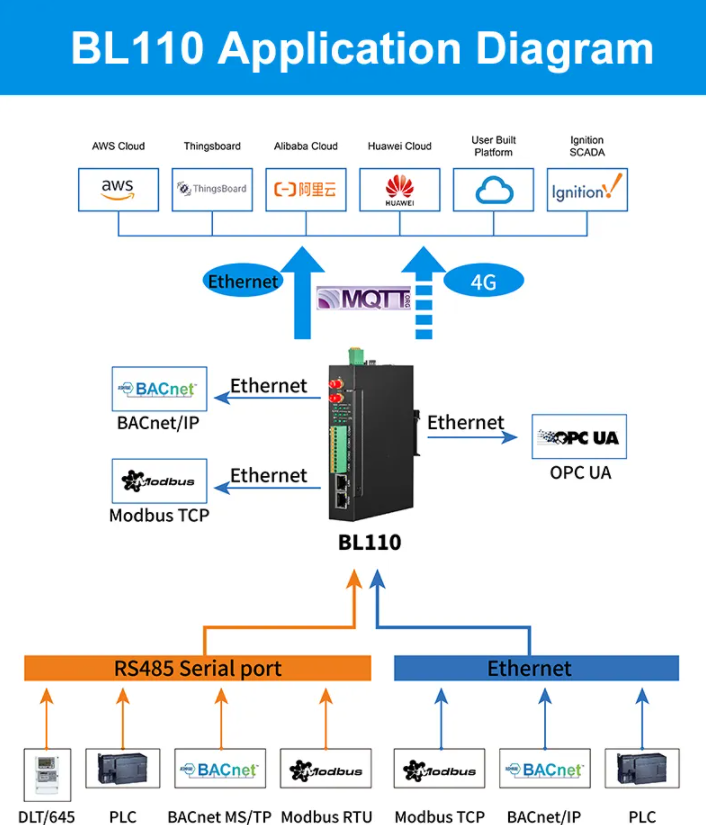

Now we will introduce an embedded OPC UA gateway BL110 from BLIIOT. Users can directly connect various brands of PLCs to OPC UA servers through this embedded gateway hardware. We refer to this embedded hardware as an OPC UA Gateway. Users no longer need licenses for industrial computers or OPC UA software, which greatly reduces the cost and application difficulty.

Beilai technology adopts OPC UA protocol to connect to MES system for industrial Internet of Things field data collection.

There are two solutions:

1. Use BL200UA to directly transfer IO to OPC UA (this was introduced in the previous article);

2. Use BL110 industrial intelligence Gateway, transfer industrial communication protocols such as (Modbus, DLT645, PLC, frequency converter, IO module) to OPC UA, and connect to OPC UA server

1. What is OPC UA?

OPC Unified Architecture is a new technology created by OPC Foundation, which is more secure, reliable, neutral (independent of suppliers), and transmits raw data and preprocessed information for manufacturing sites to production planning or enterprise resource planning (ERP) systems. Using OPC UA technology, all required information can reach every authorized application and every authorized person anytime and anywhere. OPC UA is independent of the manufacturer, applications can use it to communicate, developers can use different programming languages to develop it, and different operating systems can support it. OPC UA makes up for the shortcomings of the existing OPC, adding important features such as platform independence, scalability, high availability, and Internet services. As an important communication protocol (IEC 62541) in Industry 4.0, OPC UA is also the most promising connection standard in the industrial field.

2. What is MES?

The white paper of MESA (Manufacturing Execution System Association) defines MES (Manufacturing Execution Systems): "The manufacturing execution system transmits information to optimize the production process from order to finished product.

MES is not just a single information system of a factory, but a system integrated horizontally, vertically, and between systems, the so-called management system, for various enterprise information systems that have been paid attention to in recent years, such as SCP, ERP, CRM, and data warehouses. For example, as long as the object of the factory is included, MES is inseparable. To sum up, MES can be summarized as one purpose - how to execute manufacturing, two core databases - real-time database and relational database, two communication interfaces - interface with control layer and interface with business planning layer, four key functions - Production management, process management, process management and quality management, etc.

3. What is the relationship between OPC UA and MES?

As a functional module of MES, the data acquisition system is responsible for providing basic monitoring data for MES and is an important part of MES. OPC technology, as the underlying data acquisition technology often used in MES, is widely used in MES data acquisition systems. OPC UA technology is a new technology proposed by the OPC Foundation, the purpose is to eliminate its limitations on the basis of satisfying the functions of classic OPC technology.

4. Why MES manufacturers choose OPC UA

1. The OPC UA network protocol will not be blocked by the technology of the buying country!

2. Data encryption, high security, can pass through the firewall.

3. OPC UA is a unified framework and will not be limited by platforms such as windows and lunix. OPC UA can be deployed on PCs, mobile phones or embedded devices. In addition, OPC UA can also run naked without an operating system.

4. There is no limitation of programming language C#, C++, python, java can be used as OPC UA programming language.

5. OPC UA has been ecologicalized, and there are various products, no matter what level, from small sensors to large server data centers, the products are very rich.

The concept of Industrial Internet of Things and Industry 4.0 is very hot now, and OPC UA is playing a key role in it. As long as it is an enterprise with a manufacturing and processing plant, the use of OPC UA must be an inevitable trend.

How to realize the conversion of IO signals, sensor signals, PLC and other field device data to OPC UA in the process of industrial intelligent digital transformation?

There are two mainstream methods:

1. Convert on-site data to OPC UA through software such as kepware;

2. Install PLCs that support OPC UA such as (Siemens S7-1200, Mitsubishi FX-5U, etc.). The method has the problem of cost!

Beilai Technology BL110UA OPC UA Gateway, as a cost-effective industrial intelligent gateway, supports converting field devices to OPC UA protocol! The problem that originally required thousands or even tens of thousands of dollars to solve can be solved with a few hundred yuan! At present, Beilai Technology BL110UA can collect hundreds of industrial field communication protocols including Modbus, DLT645, and PLC protocols to meet the needs of most customers!

As a member unit of OPC UA Foundation, Beilai Technology actively participates in the promotion of OPC UA, and is committed to the research and development and production of OPC UA related products!

At present, most PLCs on the market are connected to OPC UA Server through OPC UA software running on industrial PCs, which requires both industrial PCs as hardware and the purchase of OPC UA licenses, which is expensive.

Now we will introduce an embedded OPC UA gateway BL110 from BLIIOT. Users can directly connect various brands of PLCs to OPC UA servers through this embedded gateway hardware. We refer to this embedded hardware as an OPC UA Gateway. Users no longer need licenses for industrial computers or OPC UA software, which greatly reduces the cost and application difficulty.

Beilai technology adopts OPC UA protocol to connect to MES system for industrial Internet of Things field data collection.

There are two solutions:

1. Use BL200UA to directly transfer IO to OPC UA (this was introduced in the previous article);

2. Use BL110 industrial intelligence Gateway, transfer industrial communication protocols such as (Modbus, DLT645, PLC, frequency converter, IO module) to OPC UA, and connect to OPC UA server

OPC Unified Architecture is a new technology created by OPC Foundation, which is more secure, reliable, neutral (independent of suppliers), and transmits raw data and preprocessed information for manufacturing sites to production planning or enterprise resource planning (ERP) systems. Using OPC UA technology, all required information can reach every authorized application and every authorized person anytime and anywhere. OPC UA is independent of the manufacturer, applications can use it to communicate, developers can use different programming languages to develop it, and different operating systems can support it. OPC UA makes up for the shortcomings of the existing OPC, adding important features such as platform independence, scalability, high availability, and Internet services. As an important communication protocol (IEC 62541) in Industry 4.0, OPC UA is also the most promising connection standard in the industrial field.

2. What is MES?

The white paper of MESA (Manufacturing Execution System Association) defines MES (Manufacturing Execution Systems): "The manufacturing execution system transmits information to optimize the production process from order to finished product.

MES is not just a single information system of a factory, but a system integrated horizontally, vertically, and between systems, the so-called management system, for various enterprise information systems that have been paid attention to in recent years, such as SCP, ERP, CRM, and data warehouses. For example, as long as the object of the factory is included, MES is inseparable. To sum up, MES can be summarized as one purpose - how to execute manufacturing, two core databases - real-time database and relational database, two communication interfaces - interface with control layer and interface with business planning layer, four key functions - Production management, process management, process management and quality management, etc.

3. What is the relationship between OPC UA and MES?

As a functional module of MES, the data acquisition system is responsible for providing basic monitoring data for MES and is an important part of MES. OPC technology, as the underlying data acquisition technology often used in MES, is widely used in MES data acquisition systems. OPC UA technology is a new technology proposed by the OPC Foundation, the purpose is to eliminate its limitations on the basis of satisfying the functions of classic OPC technology.

1. The OPC UA network protocol will not be blocked by the technology of the buying country!

2. Data encryption, high security, can pass through the firewall.

3. OPC UA is a unified framework and will not be limited by platforms such as windows and lunix. OPC UA can be deployed on PCs, mobile phones or embedded devices. In addition, OPC UA can also run naked without an operating system.

4. There is no limitation of programming language C#, C++, python, java can be used as OPC UA programming language.

5. OPC UA has been ecologicalized, and there are various products, no matter what level, from small sensors to large server data centers, the products are very rich.

The concept of Industrial Internet of Things and Industry 4.0 is very hot now, and OPC UA is playing a key role in it. As long as it is an enterprise with a manufacturing and processing plant, the use of OPC UA must be an inevitable trend.

There are two mainstream methods:

1. Convert on-site data to OPC UA through software such as kepware;

2. Install PLCs that support OPC UA such as (Siemens S7-1200, Mitsubishi FX-5U, etc.). The method has the problem of cost!

Beilai Technology BL110UA OPC UA Gateway, as a cost-effective industrial intelligent gateway, supports converting field devices to OPC UA protocol! The problem that originally required thousands or even tens of thousands of dollars to solve can be solved with a few hundred yuan! At present, Beilai Technology BL110UA can collect hundreds of industrial field communication protocols including Modbus, DLT645, and PLC protocols to meet the needs of most customers!

As a member unit of OPC UA Foundation, Beilai Technology actively participates in the promotion of OPC UA, and is committed to the research and development and production of OPC UA related products!

Related News

Read More >>